The brewery of gourmets

The Brew Society is a brewing community for beer enthusiasts. In The Brew Society we brew beer to your heart's content.

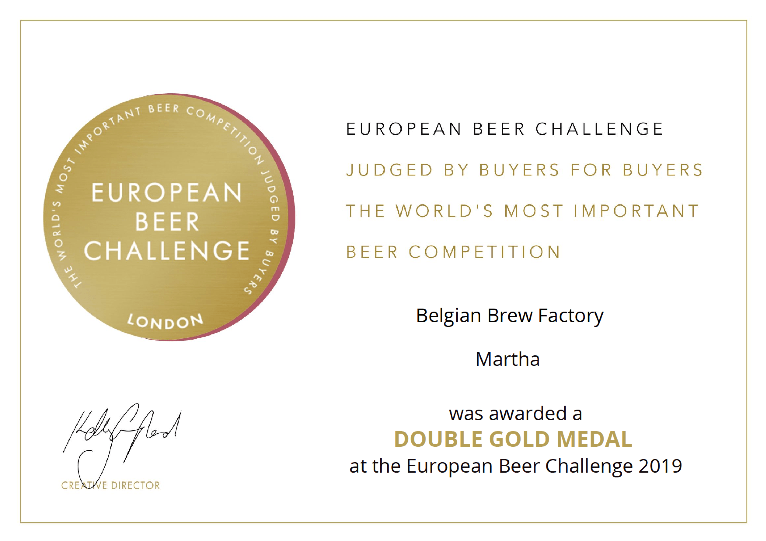

Our master brewer and his team have more than 100 years of experience. You can taste that knowledge in our seductive Martha and in our mischievous Seven Sins who see life in an artisanal way in our brewing room.

We do our own thing and in our society of brewers and gourmets there is plenty of experimentation with flavors and foams from lager to sour beer.

Life is brewtiful bij The Brew Society

Bjorn desmadryl

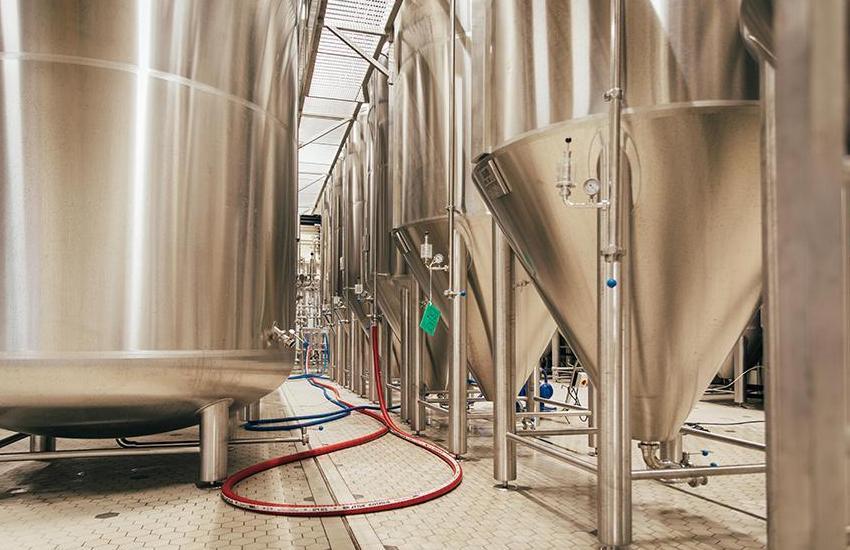

Our master brewer and his team boast over 15 years of experience. We brew bottom-fermented beers and top-fermented ales in our microbrewery starting from 50hectolitres and can brew up to 500hectolitres a day in our large brewery. The Brew Society is also certified organic. We’re locally minded, partner with local farmers and use products that are 100% Belgian. All our beers and beverages are tested on-site at our brewing lab with our analytical services.

The Brewery

- Solar panels and a water purification system for sustainable & environmentally friendly brewing

- Total surface area of 13,000 m²

- A new Braukon brewing installation

- Cutting-edge Krones filling line for bottles, cans and barrels

- German, stainless steel fermenters with a capacity of 50,000 hl/year to be expanded to 100,000 hl/year

- Fine dosing HopGun for dry hopping

- Duty-free warehouse

- Fully equipped laboratory on-site

Contractbrewing

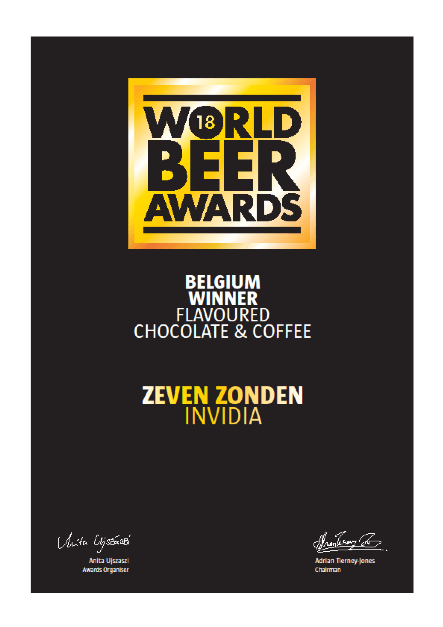

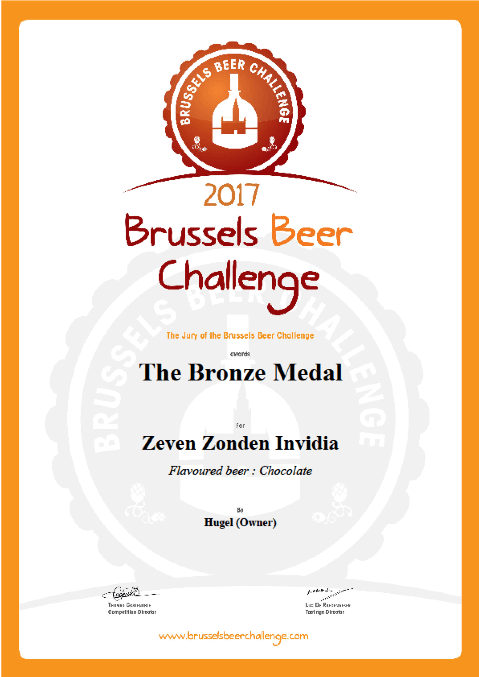

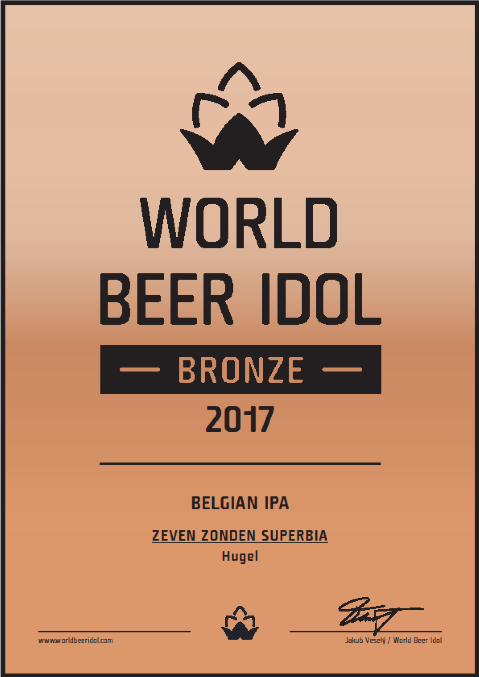

The medals